1.Materials

2.Specification

3.Application

4.Storage and shipment

5.Notice

This product is composed of square (smooth) aluminum film+butyl rubber+release film (as shown in the right picture). Aluminum film is composed of thin film and metal aluminum, which mainly provides waterproof performance and high strength; Butyl rubber is a blend of butyl rubber, polyisobutylene and other main raw materials, providing excellent adhesion and follow-up; The isolation film is the protective material of the adhesive tape, and it needs to be removed from the adhesive tape before use.

Components:

| Name | Percentage |

| butyl rubber | 10~25 % |

| polyisobutylene | 20~40 % |

| talcum powder | 20~30 % |

| calcium carbonate | 20~30 % |

2.Specification

Butyl rubber is a kind of self-adhesive waterproof sealant made of one-component butyl rubber through advanced technology, which has good adhesion to metal, wood, stone, plastic and concrete.

2.1 Advantages

contains any solvent, which is safe and environmentally friendly, and conforms to GB 18583-2008

"Limit of harmful substances in adhesives for interior decoration materials";

permanent curing, good adhesion, sealing performance and dimensional stability;

chemical stability:

excellent chemical resistance, weather resistance and corrosion resistance;

good high and low temperature resistance,

type 1: no flowing, cracking and deformation at 120℃, no crack at -40℃, no separation of adhesive layer and aluminum film;

Type 2: no flowing, cracking and deformation at 80℃, no

slip ≤2mm, no crack at -30℃, no separation of aluminum film on adhesive layer

> simple construction and

operation process;

2.2 Disadvantages

> easy to age at higher temperature (above 150℃);

> at low temperature (below -25℃), the elasticity is easily lost.;

3.Application

The advantage of using adhesive tape in waterproof engineering is to enhance the impermeability of waterproof layer joints. The waterproofing materials of coiled materials are prone to problems at the joints, edges and special-shaped parts. If adhesive tape is used in this part, it can meet the requirements of bonding, waterproofing and sealing between coiled materials and between the surfaces of coiled materials without substrate, and it can effectively play a whole waterproof role. The expansion joint can be treated with

adhesive tape in waterproof engineering of coatings and rigid materials, which can prevent the leakage

caused by the deformation of this part and the cracking of the rigid waterproof layer. The joints of various boards are suitable for water-tight treatment with adhesive tape, such as PC board lighting roof, color steel board roof and various light board materials roof.

(1), the new project roof waterproof, underground waterproof, waterproof treatment of structural construction joints and polymer roll lap sealing; (2) The steel structure building workshop is used for air tightness, waterproof and shock absorption at the joints of color steel plates; ③ Used for bonding cement, wood, PC, PE, PVC, EPDM and CPE materials; (4) It is used for waterproof and airtight treatment of the joint, end-receiving part and special-shaped part of special-shaped materials in waterproof engineering; ⑤ Air-tight waterproof treatment for doors and windows of civil

houses, air-tight waterproof treatment for ventilation pipes, etc. ⑥ Treatment of leakage of metal plate roof and cement roof, overlapping of color steel plate and lighting plate, and sealing of the joint of falling gutter.

4.Storage and shipment

Storage:Store in a cool, dry, well-ventilated place where direct sunlight cannot shine, away from heat sources, ignition sources and volatile solvents.;

Temperature:5~40℃ ;

Advised storage date:24 months;

Shipment:Products should be protected from sun, rain, impact and extrusion packaging during

transportation; According to the transportation of non-dangerous goods, the packing box has more than five stacking layers.

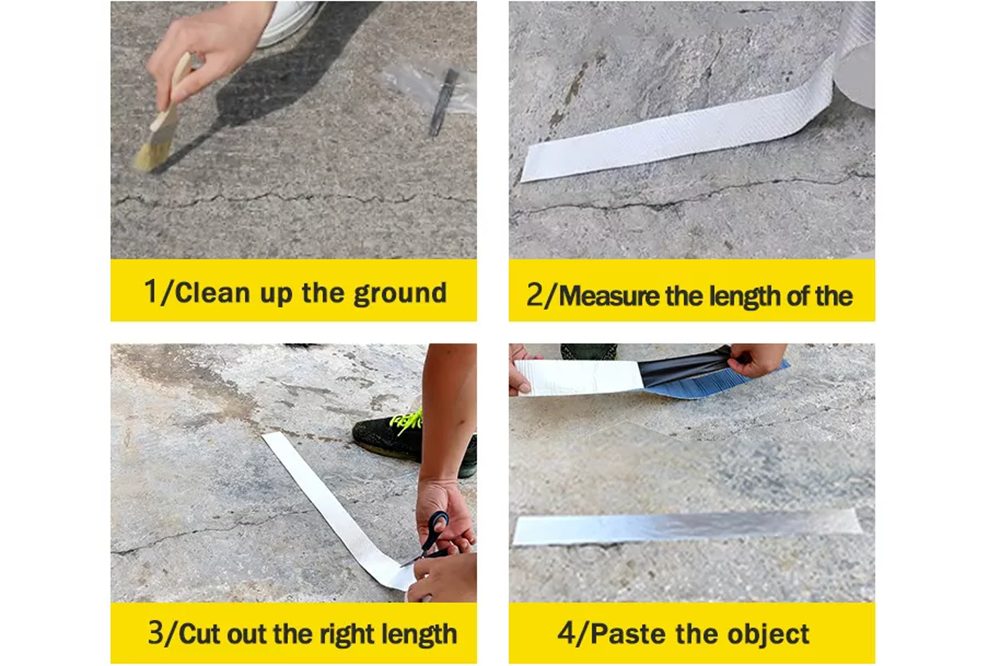

5.Precautions for construction

> Before construction, preparations should be made, and the bonding sealing surface must be dense, firm, dry and clean, and it must be stained with dust, low-strength bumps, oil pollution, moisture, etc.

> during construction, it should be attached in turn along the base surface, and it is forbidden to stretch (otherwise, the situation in the picture on the right will appear), and the effect will be better after rolling by hand or pressure roller;

> after washing with water, the base surface must be completely dry before construction;

> in order to ensure the bonding strength, the suggested construction temperature is 5~35℃;

> within 24 hours after construction, the joint can be torn and peeled off;

> please do not use waterproof materials containing organic substances such as benzene, toluene, methanol, ethylene and silica gel at the same time.